Description

50 Kg 5gm 400×400

100 Kg 10gm 500×500

200 Kg 20gm 500×500

300 Kg 50gm 600×600

500 Kg 50gm 600×600

500 Kg 50gm 750×750

1000 Kg 100gm 750×750

1000 Kg 100gm 900×900

1000 Kg 100gm 1000×1000

1500 Kg 200gm 1000×1000

2000 Kg 200gm 1200×1200

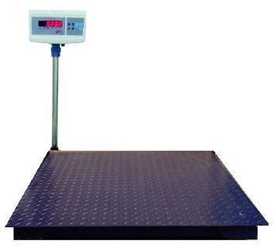

Platform Weighing Scale

Application

Commercial

Market Yards

Warehouses

Logistics. etc.,

Features for Platforms Scales

Heavy structure by in-house fabrication

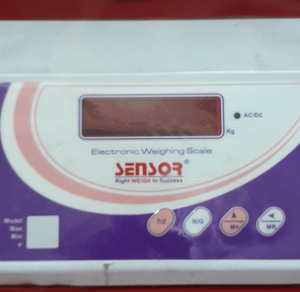

Advanced micro-controller based design

Easy to read six digit bright LED display

Very low power consumption

Battery level indication

High precision load cell

Digital calibration

Compact design with SS or MS platform

8 hours battery back-up

Power saver mode

Over load indication

Options

Wall mounting display

RED or GREEN display

Counting facility

RS232 Computer interface

Customised platform size

Technical Specifications

Operating voltage 190 -220 AC

Battery 6V – 4.5ah

Frequency 50 Hz

Operating temperature 20 – 50˚C

Operating humidity 95%RH max ( non-condensing)

Power consumption 10 watts (approx.)

Display 7 segment LED

Need to weigh larger goods in an accurate manner? The most customary industry-used scales are digital platform weighing scales. Platform scales are used wherever the industry uses bulk capacity goods for a sturdy construction. Most manufacturing companies use electronic platform weighing scales to check out the weights of large sacks and other objects. Other than this, these scales have consistent usage by veterinarians, farmers, food processors and even in airports.

Building blocks of Digital Platform Weighing scale

Flat Platform

A sizeable platform with distinguished varieties in sizes, load capacities and designs used to transmit the weight of the loaded goods or objects to internal measuring devices fitted in the equipment

Load cell & Transducer

Signal Conditioner

Signal Conditioner amplifies and filters both input and output signals. The output signals are diminutive and measured in millivolts for digital display.

Microcontroller

Digital display

Considerations for Digital Platform Weighing Scale

Capacity

Accuracy

Durability

Size of Platform

Adaptability

Linearity

Readability

Usability and portability

Affordability

Weight drift

Benefits of Digital platform weighing scales in industries

Let’s explore the fringe benefits of platform scales usage in manufacturing units

Range of activities

Improvement in productivity

Comply with regulations

Simple to record data

Materials for construction of Digital Platform weighing scales

The platform scales are built with tough and rigid materials of stainless steel, carbon steel and aluminum which can hold heavy loads and materials. The manufacturers should choose corrosion-resistant materials for better durability of platform scales. Rugged platforms are also preferable for preventing slipping of loads when positioned.

Reviews

There are no reviews yet.